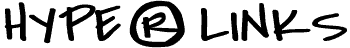

Walker-Turner Drill Press DP 900 / 936? Mid 40’s

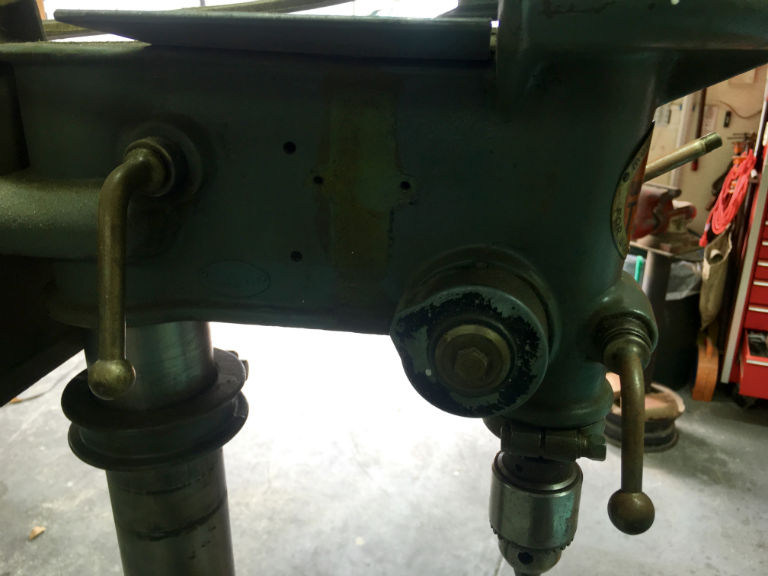

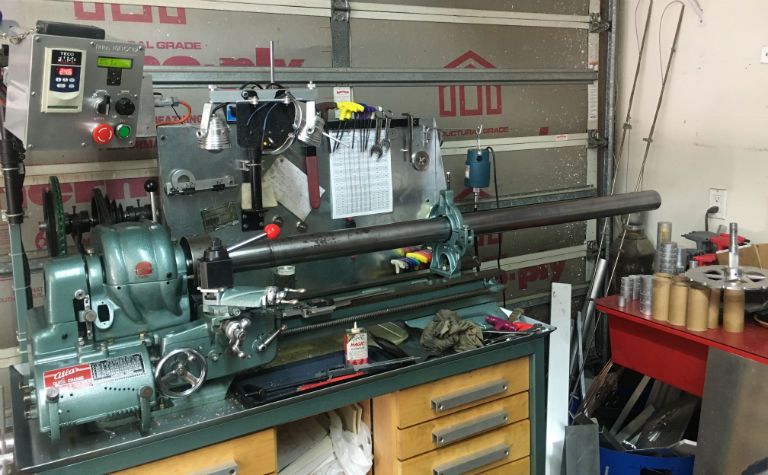

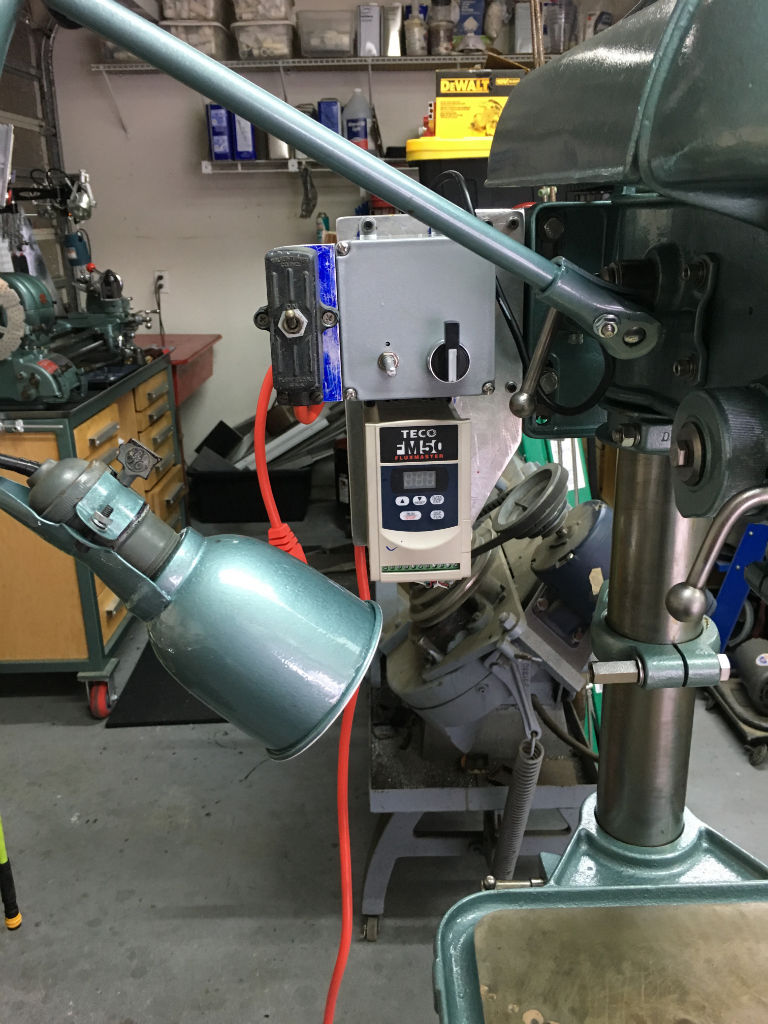

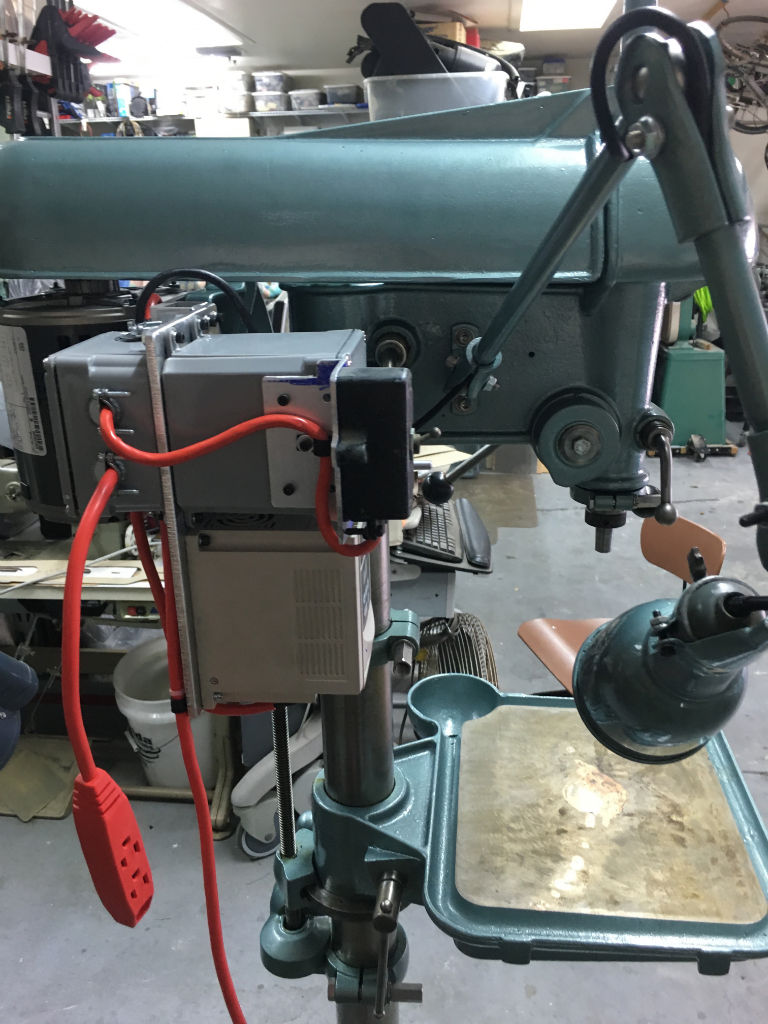

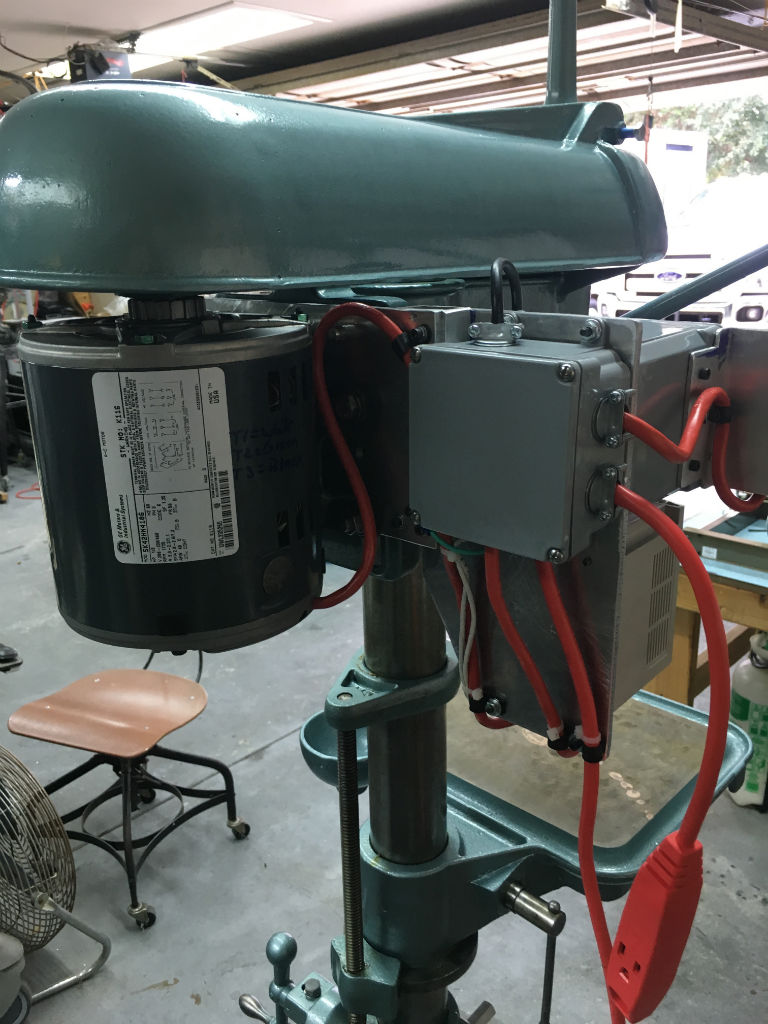

I acquired this drill press having visited a friend of mine. Pete @ Monopoly Marine He was kind enough to let me take it off his hands. (Many thanks Pete!). Having loaded it up in my truck I quickly took it back to my shop and failed to re assemble it . This would have allowed me to take some pics. (PRE). Sadly I did not. But I did manage to take some pre pics. ( See below. ). Having inspected the parts while disassembling. I already had an end game in mind. Replace the motor with a VFD. Lucky me I already had a new TecoFM50 in the box. Also I Had a 3 phase .5hp motor too.but upon inspection it was not a keywayed shaft. Rather than add the keyway I found one on ebay for $70.00 delivered. Also I intended on adding a reversing switch, as well as a digital RPM gage (yet to be added soon though), as well as a digital depth gage. I replaced the belt with a link belt. easier to adjust and also does not imply I need to remove the front spindle assembly should it break. Also worth noting the motor pully wobbled quite a bit So I elected to replace it. As well as most all nuts and bolts 90% is all Stainless now. I stripped all the parts down to the metal. either by wire wheel or glass beading… in preparation for paint. The main work table had some (many) mis drilled holes in it. While I knew I would cover the table up with a new work surface I figured now is the time to visit it. I intended on having it welded up. I loaded the table up and off to see “Joe” from Daniels welding. He is my local goto expert when it comes to welding.

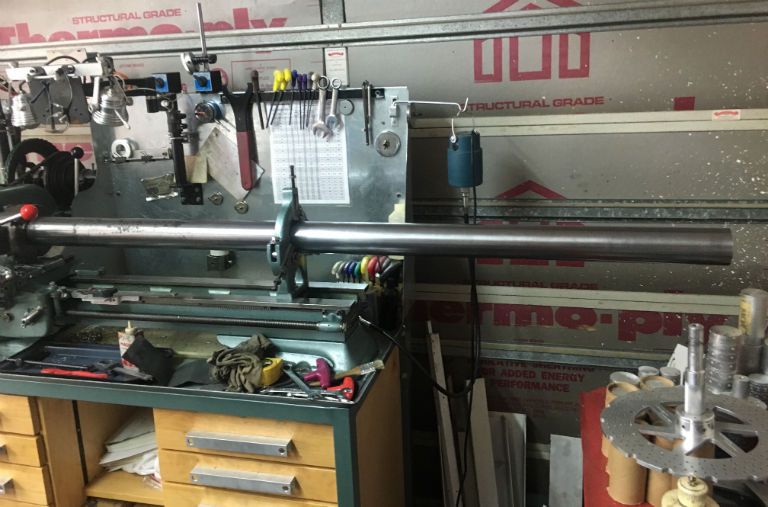

The main upright (2.75″) steel pipe/tube was not in bad shape at all but I decided to see if I could clean it up. So on my lathe it went. I think it took all of about 30 mins to get it setup and cleaned. this part was very satisfying.

Specs:

- Walker Turner DP 900 series

- Serial Number#

- Sold By: Ellfeldt Hardware & Machinist supply Kansas City, Montana.

- Full size standing aprox 6′

- Jacobs Chuck Taper 33

- Quill has +/- 4″ down travel.

- Throat depth is:

- Table height adjuster is Acme Screw driven.

Now that its mostly assembled. All thats left is. (parts are still coming in)

- Remount all the badging

- Add in the Tachometer ie RPM gage.

- Add in the Digital Depth gage

- Add/make the quick release depth stop nut.

- add knob to speed adjustment pot.

- fabricate a nice faceplate for the control panel.

- repaint the on off switch

- decide on a caster plate setup for ease of moving.

- finish making knurled hand nuts for quick tightening areas.

- Use the hell out of it…

Perhaps a small amount of additional info.

A link to many other same style drill press can be found here. and the most notable one / similar one here with a spectacular build log

Walker Turner history

I’d like to buy the table lit mechanism from you.

Seawoolf11@hotmail.com

Not sure what good it would do me to sell the lift mechanism. I’d be left with a drill press and no table. I might consider selling the entire drill press but Parting out machinery is not my style.

Thanks for the offer though.

-S-

pretty darn nice

Just came across this page when I googled Walker Turner drill press. I live in Calgary and restoring a similar drill press and wonder what colour and manufacture paint did you used for restoring this drill? Also, you still have the drill? Thanks.

Dai

Dai,

Thanks for the inquiry. I used Rustoleum Hammer finish green out of the spray can. Yes I still have the Drill press. -S

If you ever considered selling your drill, contact me first. I would love to own that drill. I live in Calgary also. Thanks for the paint colour tip.

I’ll be certain to keep you in mind. & Thanks again. I do ahve a send drill press its the same model but with different options. Not as many of the nicer options to speak of.

But its a great parts machine. Send me some pics of you drill press. I’d love to see em. -S

I will send you pictures when I’m finished with my restoration. Right now I haven’t even started yet. How do I send you pictures? I guess the moderator edit my message before they posted because they removed my contact. LOL.

Greetings, I am working on a universal table lift kit. I already make a speed reduction kit. Can you tell me what the TPI of the lift screw is? Also, is it geared one to one or like 2 to 1. Looks like the gear on the screw is bigger than on the crank. I presume it’s a single start Acme thread. Very nice! I have a similar shop though stuffed with more. Atlas QC42 among 12-14 others, Atlas Mill, Too many drill presses and etc….

Dave, Ill see if I can get the TPI today. sorry for the late reply. -Sam

Hi. Fantastic job! I am working on a bench top Driver drill press now. It is missing the spindle cap. I noticed that yours doesn’t seem to be attached by screws. Mine doesn’t have screw holes. How do these attach to the machine? Any info would be great. I would like to find one but am not sure what the connection looks like.

Nat, Not sure what part exactly your referring to.the cover hindges on 2 pins. the actual pointy cap just sits in via gravity. and a slight pressure fit. No screws. hope that helps.\

If you don’t have a use for the original 1/3 HP motor you replaced I’d be interested in purchasing. Please let me know. Thanks!

Sorry, its already been re-purposed. Ill keep you in mind if/when I run across another.