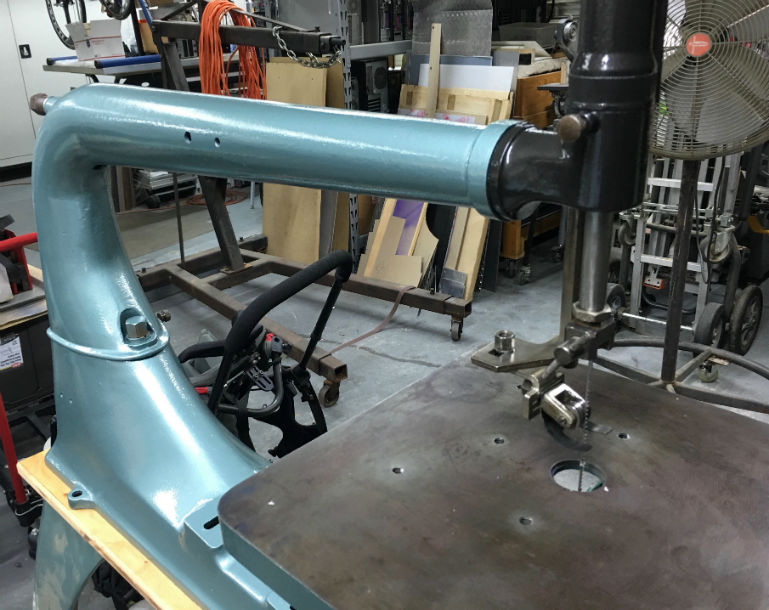

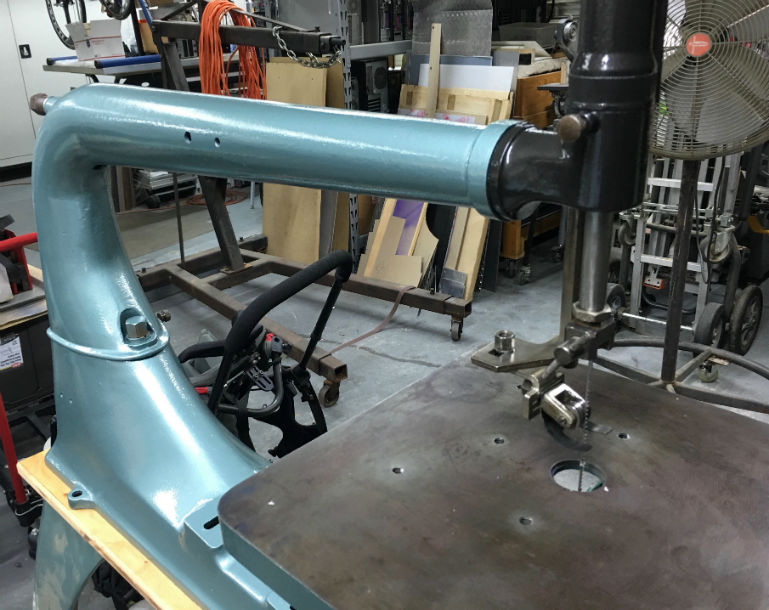

Craftsman (Aka: Walker Turner) 24" Scroll Saw 1930’s

Im nearing the end of my Scroll saw rebuild.

Having 2 of them I found the first one at a mechanic shop. We bartered the saw for some work rendered. After taking it home and doing a prelim inspection I discovered the gear/drive box was broken 1: the casting part that held the table in place was completely broke off. 2: the side of the case where the pulley was was warped. I deduced that the saw must have fallen on its side. I completely took the unit apart in hopes of repairing the case. I was able to repair the casting part that broke off. But not the warped portion where the pulley snout was. So Knowing I would not be happy with it. I started trolling the internet for replacement parts. After several months One came up on ebay. It was located in Ohio. (and me in Fla.) Hmm how to get it here if I win the auction??? Well I won the auction (it was in pretty darn good shape). Lucky for me I had a friend who lives in Ohio. Kenny was Kind enough to both pick it up and hang onto it until some was heading to Fla. well Months later It was here! So off I went. I completely took it apart. Re painted all the parts. Laser cut out new Gaskets for the motor/gear/ drive box. As well as laser cut out a new felt plunger for the air pump. Laser cut out a zero insert plate. mounted a new switch assembly. as it did not even have one. You had to plug and unplug the unit. I stitched up a new Ultra suede dust boot. for the top of the gear box plunger. new SS hardware for the entire unit. The motor base plate casting was broken so I made a new one out of aluminum. I used my old base legs from and Atlas lathe.

Post Pics below

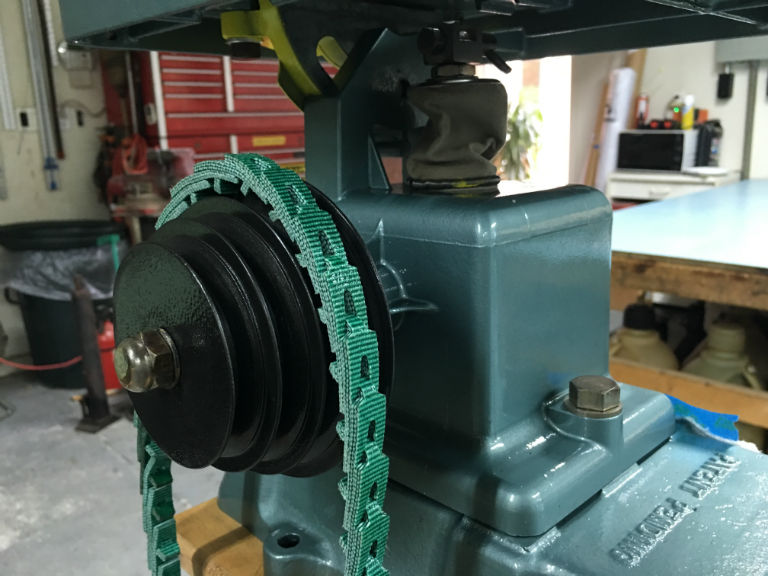

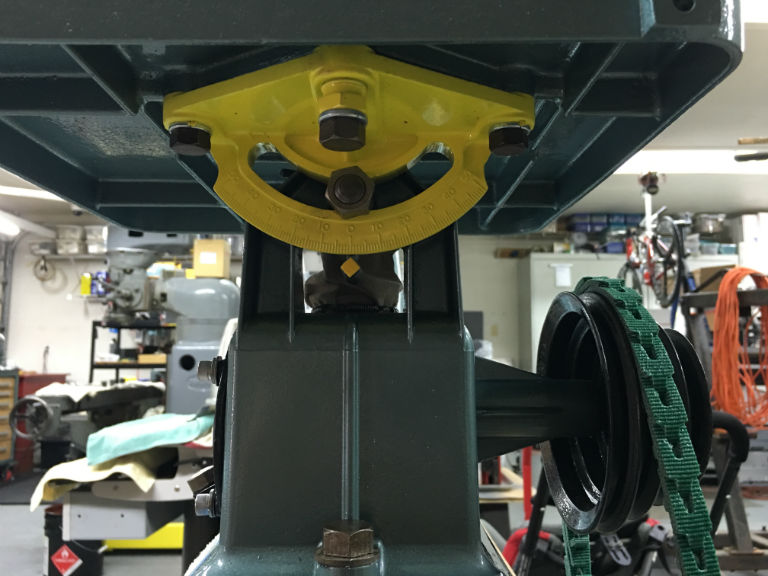

Link belts are the best!

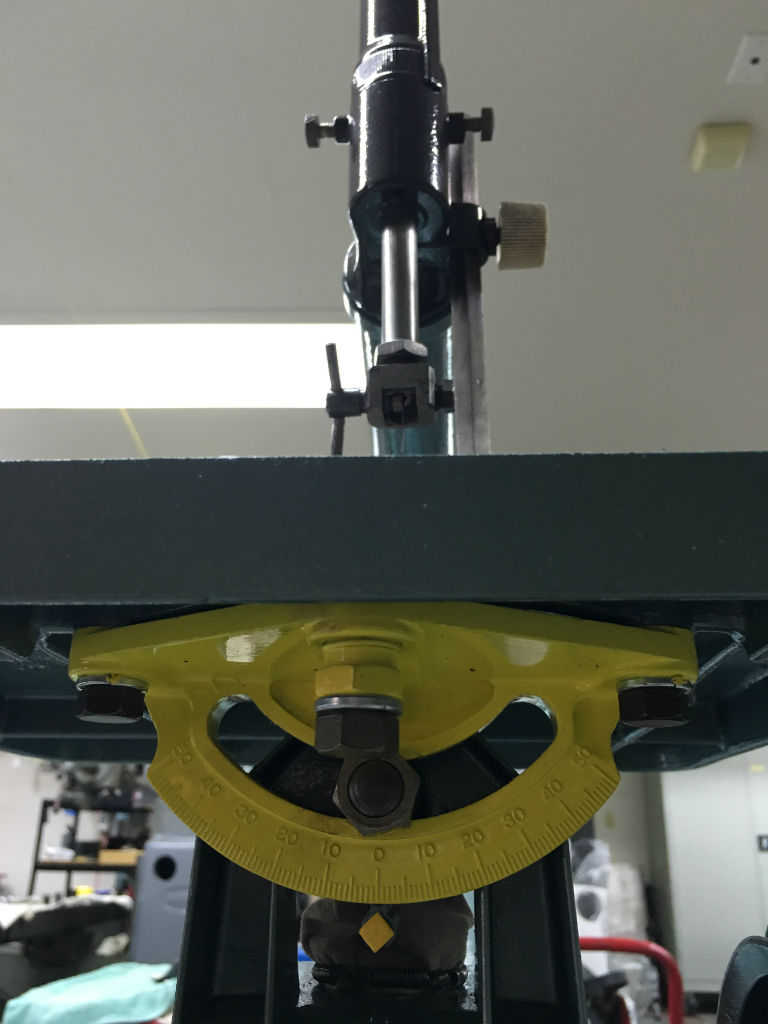

I decided the paint the entire part yellow. easier to see eh?

Not sure why all the tapped holes in the table both of them have the same ones.

Need a new switch plate. This one is temporary.

Need a new switch plate. This one is temporary.

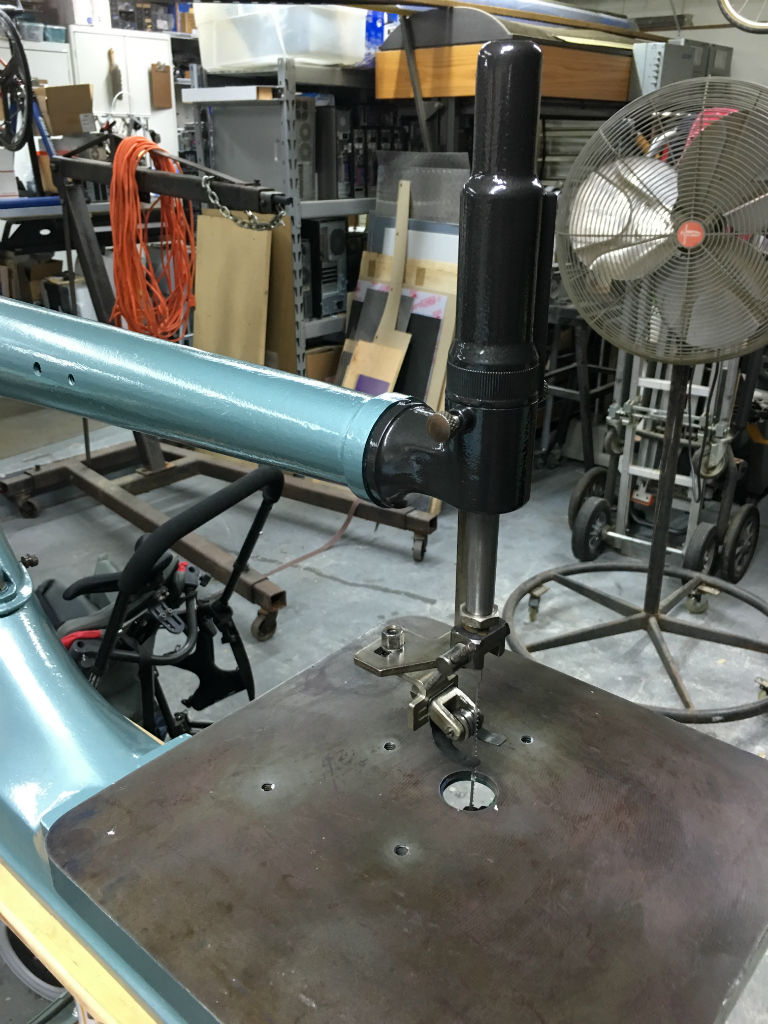

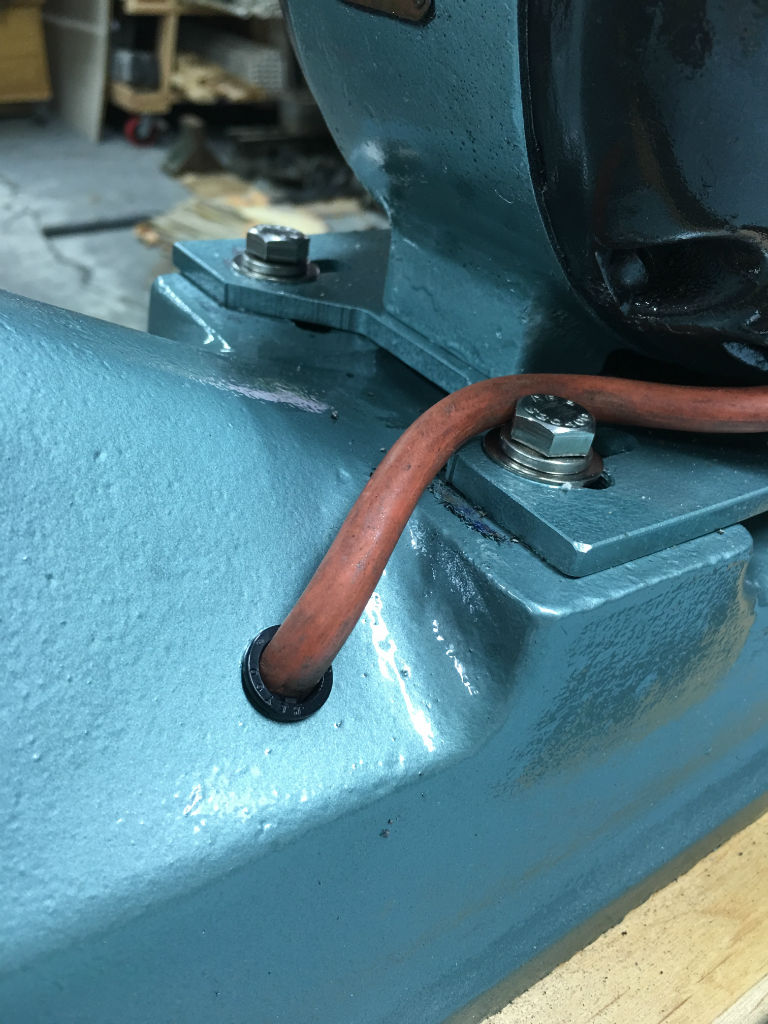

Gear/Drive box got new gaskets, and a fresh oil change too. “the works”

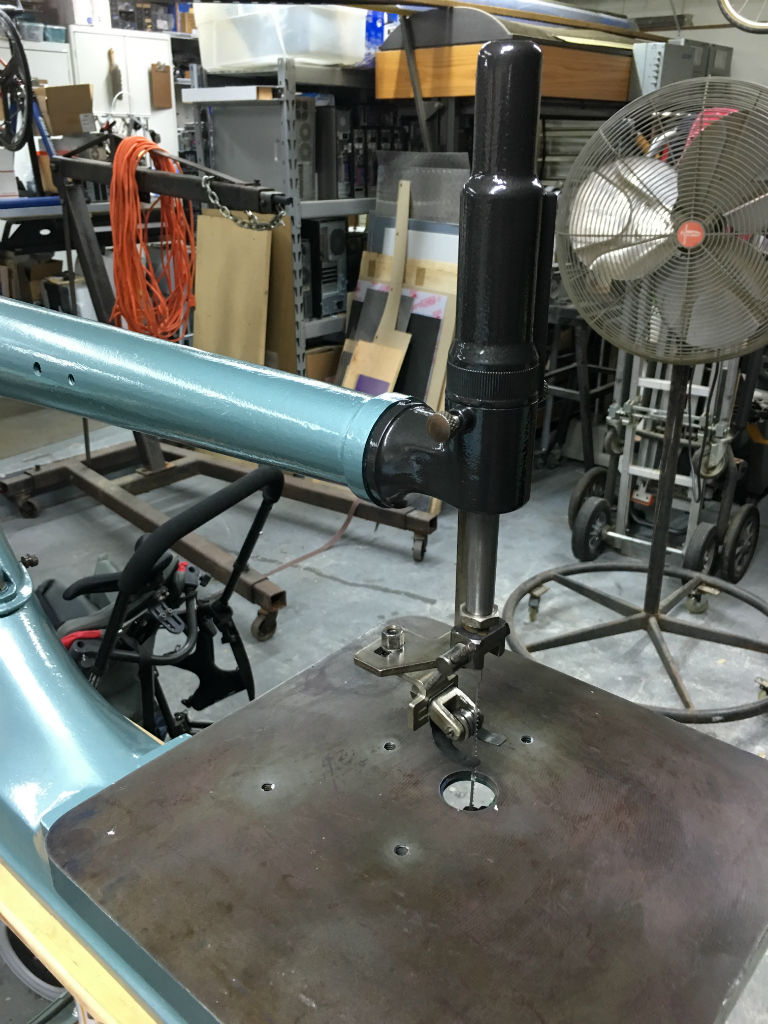

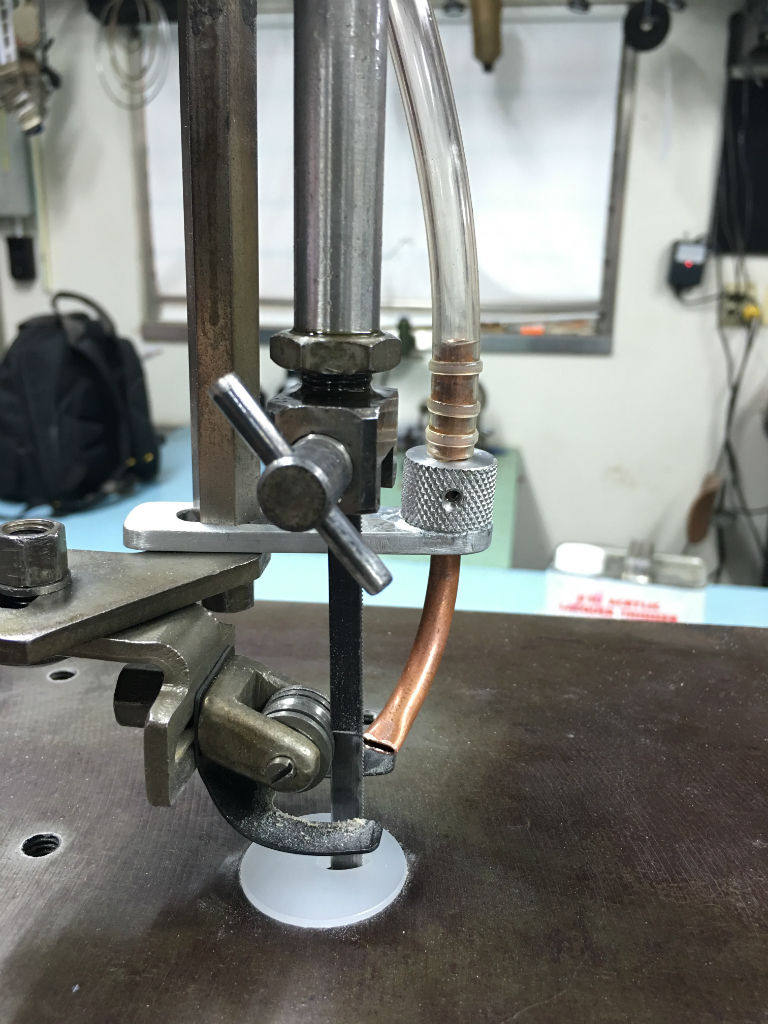

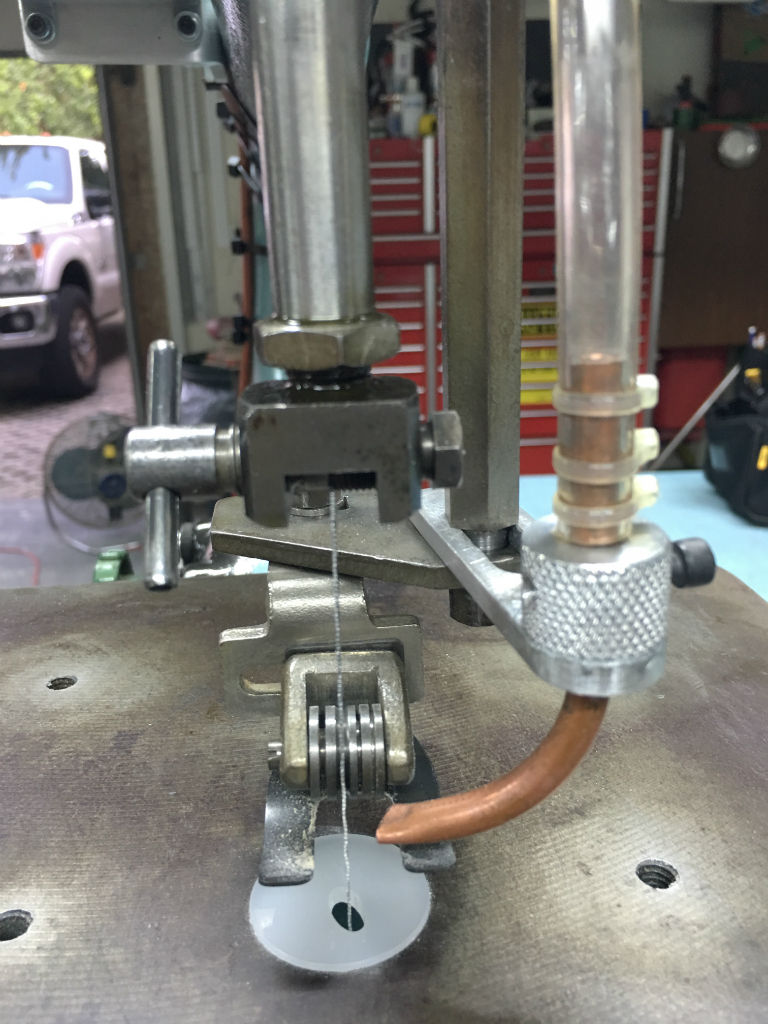

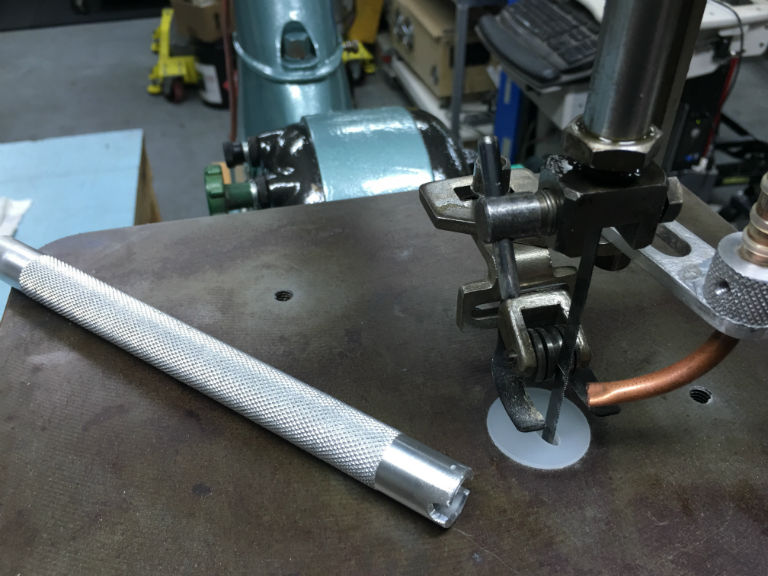

Im not to happy with the crappy air blower holder I have to come up with a new design but the old one will suffice till I can come up with a new one. I still have yet to make the Zero insert plate. but it’ll be done by the end of the day.

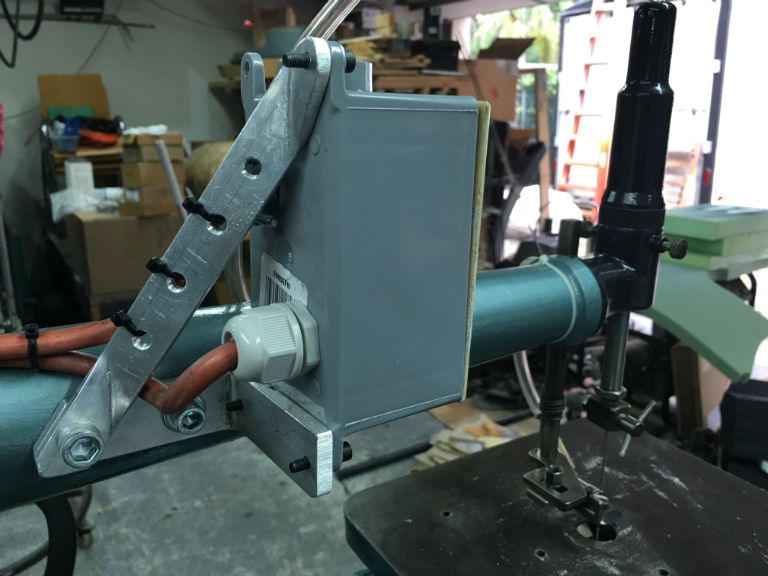

This is the switch location. I used the orig holes that were already in the upper casting.

Old Switch location mount holes? (Above)

Used the upper entry hole as a tool holder! (Above)

Surprising the motor runs darn nicely. Gotta love old parts.

Surprising the motor runs darn nicely. Gotta love old parts.

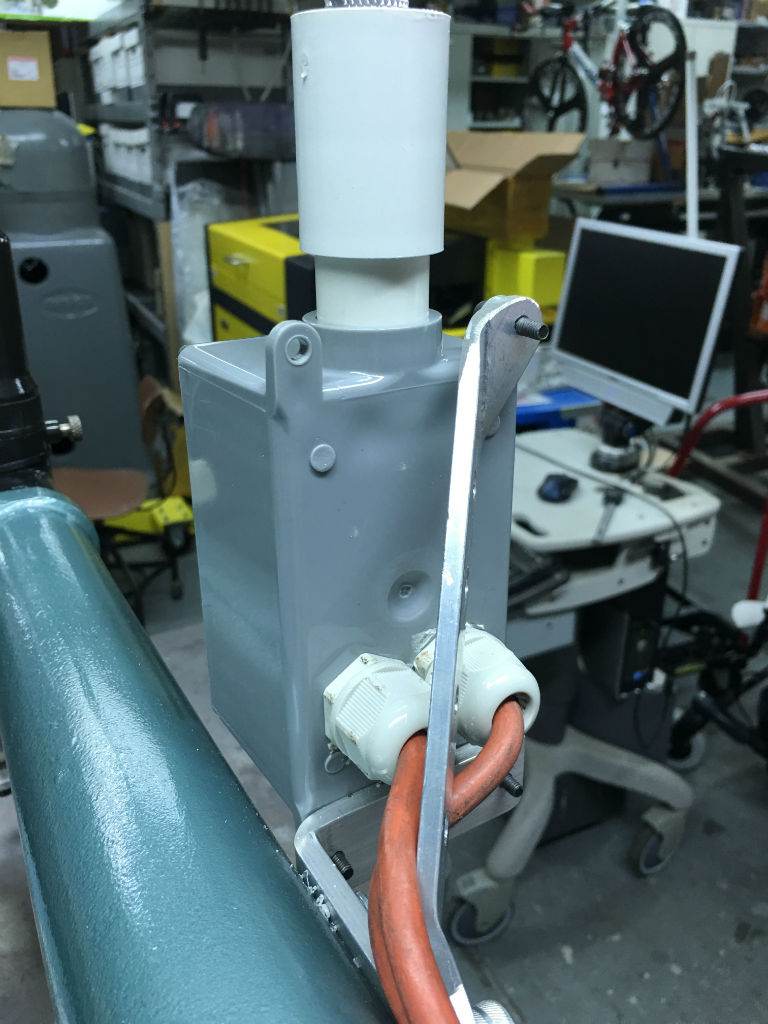

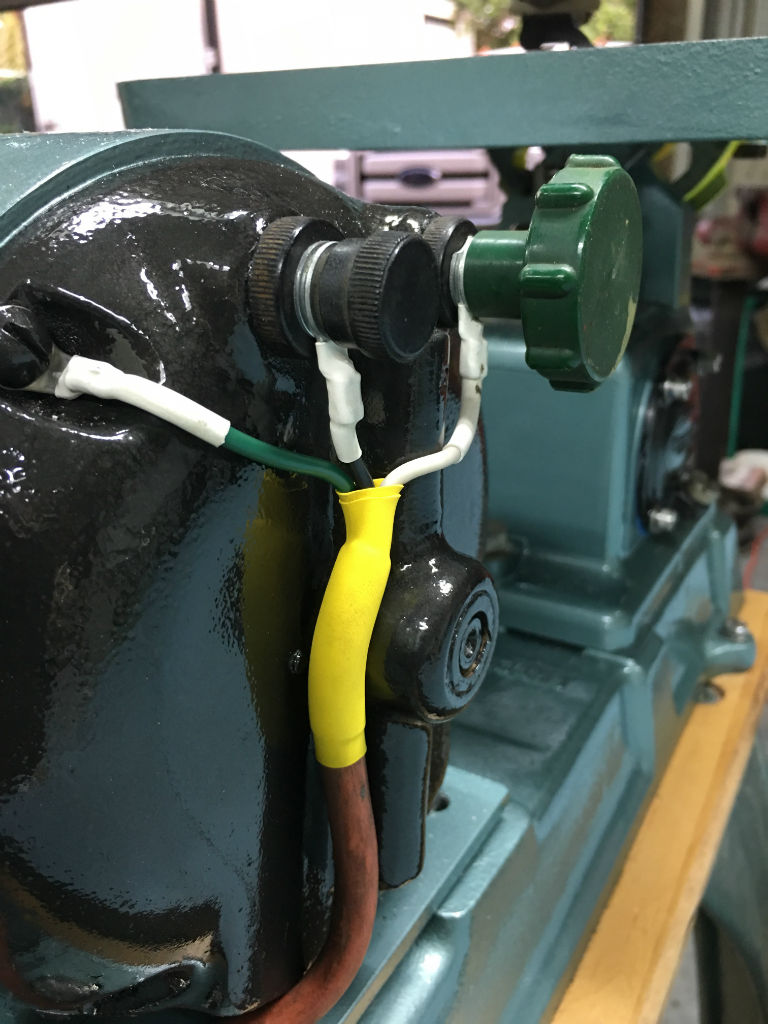

I have to clean up the wiring as I was out of nice eye ring terminals but its temporarily wired. As well as cabling restraints.

I have to clean up the wiring as I was out of nice eye ring terminals but its temporarily wired. As well as cabling restraints.

Close up of the new boot I sewed up. its made from Ultra Suede and should last many many years.

Close up of the new boot I sewed up. its made from Ultra Suede and should last many many years.

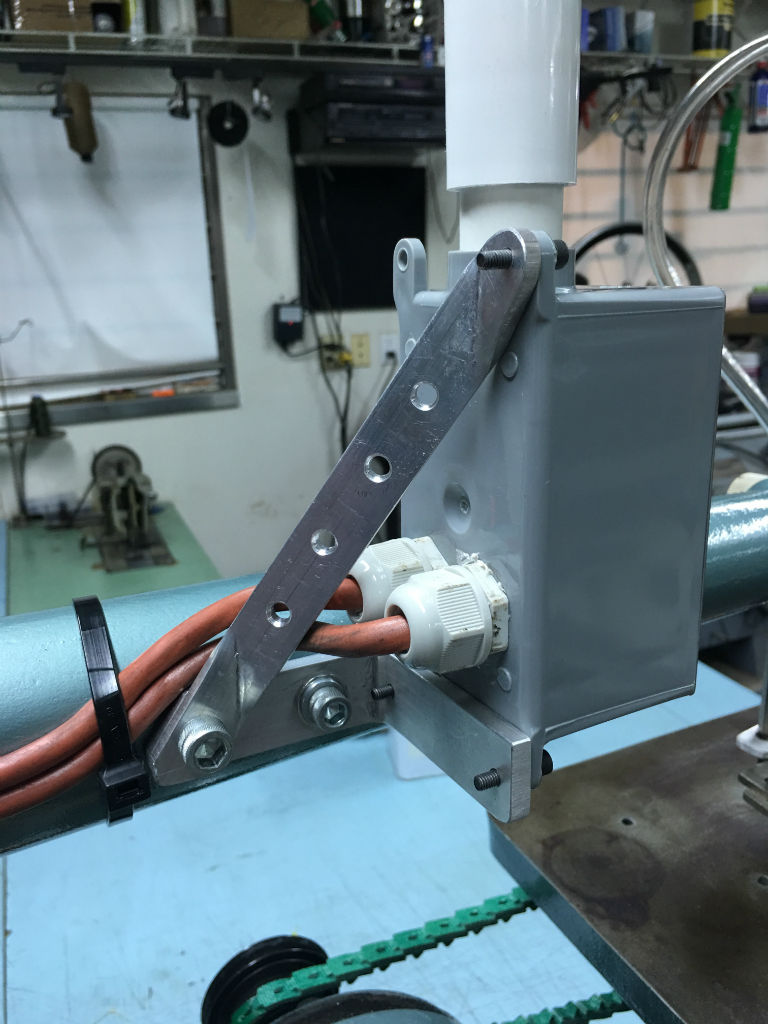

I know the Wire Straps look like crap. But I have yet to decide if I really want to drill a hole in the upper support.If and when I do the wires will be gone. it’ll look better but then I’ll have the Hole!… Just cant do it ….yet?

I know the Wire Straps look like crap. But I have yet to decide if I really want to drill a hole in the upper support.If and when I do the wires will be gone. it’ll look better but then I’ll have the Hole!… Just cant do it ….yet?

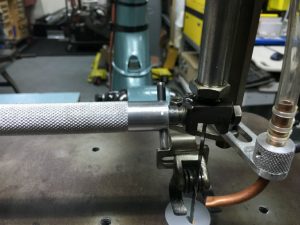

The box came with the standard hole So I decided to use it for the Blade bolt tool. Knurled alum tubing. no way to over tighten the wing bolts.

My Saw did not come with the nice blower attachment. It had some crappy spring setup. So this is my version of the blower attachment. all aluminum with a copper blow tube.

I dont think the wiring it too safe. these days a person cant fart without breaking some law somewhere. But it’s plenty safe for me. plus I like the old sk00l look of the knobs.

Probably should paint the brackets to keep it looking the same. All my projects have some unfinished piece. why should this project be any different? very Skeptical it’ll get done now. time to put this piece to work!

This is the only hole I drilled / added to the entire saw.

This is the only hole I drilled / added to the entire saw.

I have no idea what these 2 holes were for.? perhaps the power switch?

I have no idea what these 2 holes were for.? perhaps the power switch?

The knurled tool.

The knurled tool.

Still todo’s

- Clean up wiring(Done)

- Belt/pulley cover?(un-decided)

- light?(yet to be determined)

- deal with blower holder(done)

- repair/rebuild/replace the upper and lower screws that are used to tighten the blades. their both bent.(done)

- Add a small drawer to hold related parts. blades etc..(next wood project Ill make a drawer)

Oh and look for my pre pics. (having looked I have yet to find them!. Darnit…

Here is a great site “Vintage Machinery” for looking at this very model as well as many others.

Thanks! now I’ll enjoy my new to me Scroll saw!

I might be offering a partial rebuild kit for these. The parts would consist of a GearBox side gasket, Plunger gaskets, a gearbox upper bellows sock and a few zero clearance inserts.

I have collected 3 files relative to this saw. And, perhaps even yours. (all DL’s require a password.)

(Download link below)

Beautiful machine !!!

I have one just like it. I got lucky mine is all original in perfact running condition.

I also have the original use and application book if your interested in a copy.

Griff, Thanks so very much for the compliment! Yes, I am Interested. Also What/where do you source your blades from? ~Sam

Looking for blades for this saw, any ideas

Jon,

I use the typical blades the ones that have the pins in them. And then I pull the pins out. works every time 🙂

Hey, I just stumbled across this site because I was looking for the manual for this scroll saw. Any way you could email me a copy too? Thanks! Also, it would be great if you could scan the manual and upload it to vintagemachinery.org!

I am awed by the rehab. I have a similar machine that works b ut needs a lot of TLC. I am a serious (retired-70) woodworker and would love to at least clean up this machine and see if it can still perform. I am not so skilled that I can do some of the operations you described in getting your machine going but still I’d like to give it my best shot. The fellow who commented about having a manual I also just requested a copy of same. I guess I’m hoping you might be a resource to me if I go forward and try to rehab this machine. Thanks for listening. Bill Schwegler ( in Nashville ).

Bill thanks for the kind words. I’d be glad to help however I can. I’ll fwd you a copy of the manual too. 🙂

Wow. That is beautiful! Just found by grandfather’s scroll saw and it looks like the exact same one. Any documentation you could send I would be much obliged.

i have the same saw and restoring it would like to get copy of the manual

how or where can this be done

regards

Ron

Ron,

I have 3 files. combined their 35 megs?

how would you like them? emailed? let me know. -S

I would like an email copy of the manuals if possible.

Allen,

PWD sent 🙂

I have one, too. Doesn’t say Craftsman on it though. I see you don’t have a table support on yours…Mine rattles like crazy without it…The other issue I have is not knowing the length of blade that can be seen between upper & lower posts.The manual should say, and I don’t know what the tension should be…Could you look it up for me…? Thanks..! Kevin

Kevin,

Im not sure what you mean by the “Table support” could you send me a pic? Also the blade tension is completely user adjustable. when I first got mine

I played around with what works best at that moment. it varies from blade to blade and material to material. but I would say in my case a medium setting just about get most jobs done. I even went so far as to change out the spring for a higher tension one… that did not work out so well. I could measure one of my blades lengths if you still havent figured it out. best luck! S.

Just bought the same or very similar scroll saw. Just missing the tension nut on the pulley. Hope to get one tomorrow. 24 inch throat will be great once I get it up and running. Just wondering how to get a password to download the files.

Rick,

Password sent. 🙂

Sam, Great restoration! I also have one of these old saws and just pulled it fro m a dark corner of my garage, cleaned it up added oil and a new blade. When i turned it on it made a knocking/banging noise. Any idea what it could be? I don’t have a manual.

Thanks Pete

Peter,

While this is a just a guess. One day I fired up my saw. and it too made a banging noise. not typical… Scratching my head. and worried at the same time. I discovered the main pullys set screw has came loose. Just enough

the crank was slipping backwards. and the effect? a banging noise. Easy fix… tighten the pully set screw. thats all I got I hope this helps. -Sam

Hi! Nice restoration! I have the same saw that was given to me. Mine is a bit on the rough side! I’m looking for any info on this machine. I’d like to get a password to download your files please! Thanks.

Hi,

This saw looks absolutely wonderful!

I bought a similar saw, if not the very same model, a couple of years back. It’s in pretty good condition but it was owned by a machinist who swapped out the saw pulley for a pulley that is much larger in diameter so as to slow down the speed for metalworking.

I’ve been trying to find replacement pulleys for some time now but can’t find exactly what came on the original saw. Can you help me out with this? Also, the motor pulley only has one step, not like the motor pulley on your saw. I’m really trying to get it back to original condition as much as possible so either part numbers or physical dimensions would be helpful. Thank you very much!!

Daniel

Daniel. Some pics might help. I have scoured the web for publications and users manuals. pics and exploded diagrams

are about as close as you will get to determining the original state of your saw. all this if your lucky. they didnt have the internet

back then so any documentation? hard to find for most things. easy for others. BTW thanks for the kind words.

I am also restoring the same saw. I could really use a copy of the user Manuel

Can I get your contact info, I have my great grandfather’s that I would like to rebuild. Missing some parts so any and all help would be greatly appreciated.

Fantastic restoration. Just started on my great grandfathers and would love a copy of the manuel if you are still providing it. And though I am retired, plan on puting back to work in my shop.Thanks so much for preserving our American history.

Gary,

the manual is available for download right at the end of the post. click it 🙂

I just picked one of these up today, here in CO.

It appears to just need some tlc. Your restoration is very nice, will mooch on much of what you did. I have a set of old(er) Barnes lathe legs that will go great under this saw. Surprised to see so many of these still alive after all these years.

Dan, would love to see pics. if possible I did let mine go to another fan of them. I currently have a Vega I’d like to restore.

Vega is another scrollsaw fwiw. 🙂

My saw is a Craftsman by Walker Turner, what features should I look for in order to identify the “exact” model and year? It has the “tall” return spring tower, not the later tension adjuster type, so suspect about a 1937/38. Looks identical to your restored job.

Hi, looking at mine today, I can see that the lower housing is die cast aluminum, and the shaft snout had been broken and rewelded. The welds look ok, but it appears the snout is tilted upwards. It turns free, but when I take it apart, I may have to repair that. Not sure how much meat is in housing, and if I could just make up a new snout and bolt it in. I’m a retired machinist with lathe and mill, so…pix coming.

Are you making the bellows kit yet?

Thanks

Ron

Ron,

When I was nearing the completion of my saw. I though More people would reach out for a possible kit. and I was goin g to built 10/50 kits.

thats was several years ago. And to date? no real interest in a so called kit. I have since sold the saw and started a new rebuild on a VEGA

If and when I get re setup Ill contact you and send you a bellows. (Ill have to find the templates I created.) So sorry for the bead news. -S